COMPACFOAM – Dimensionally stable, pressure-resistant, screwable & moisture-resistant

No more heavy vehicles: COMPACFOAM reduces your vehicle weight – without any loss of stability

The alternative – weight saving, stability and durability

Request nowscrewable

excellent thermal insulation

excellent dimensional stability

long-term stable

frost-resistant

isotropic

Open to diffusion

ductile

highly resilient

light

Formaldehyde-free

recyclable

screwable

excellent thermal insulation

excellent dimensional stability

long-term stable

frost-resistant

isotropic

Open to diffusion

ductile

highly resilient

light

Formaldehyde-free

recyclable

Use in vehicle construction

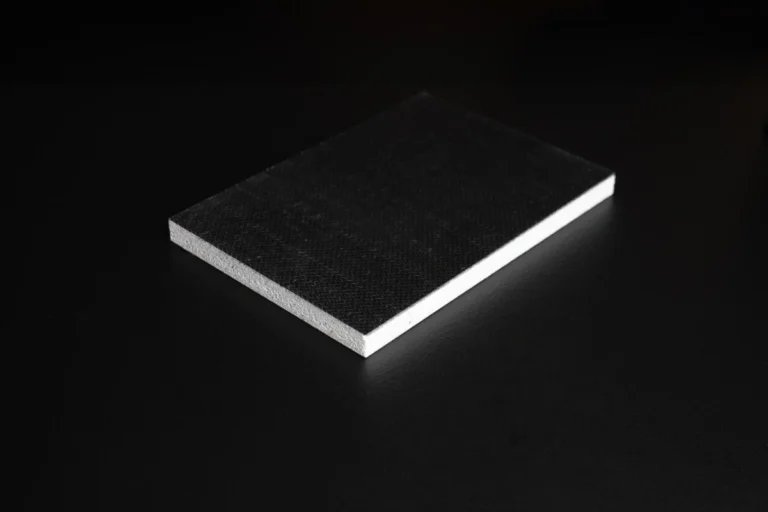

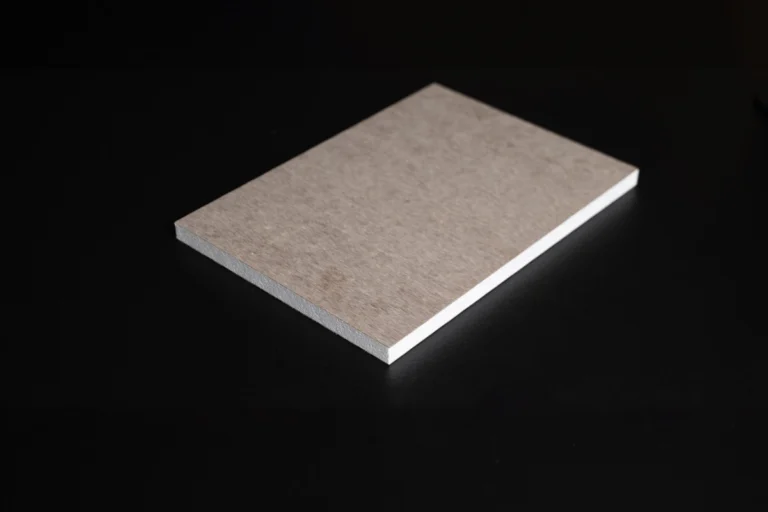

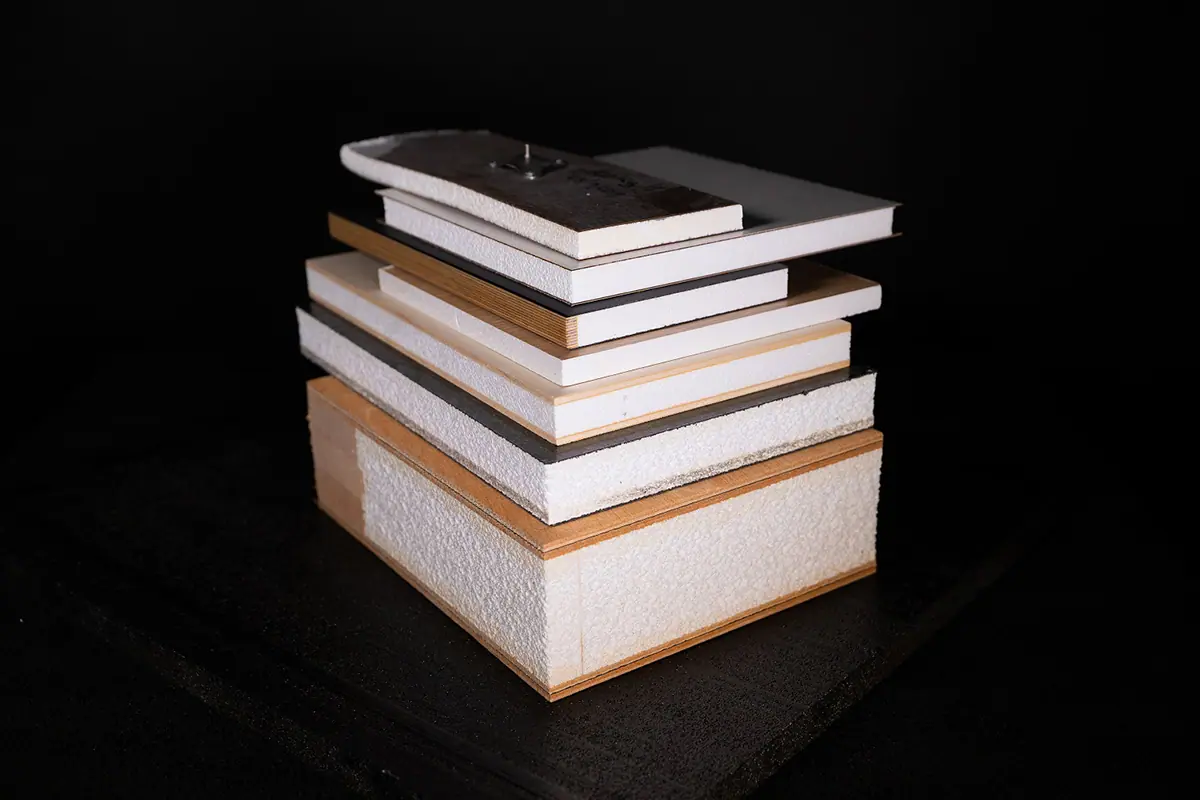

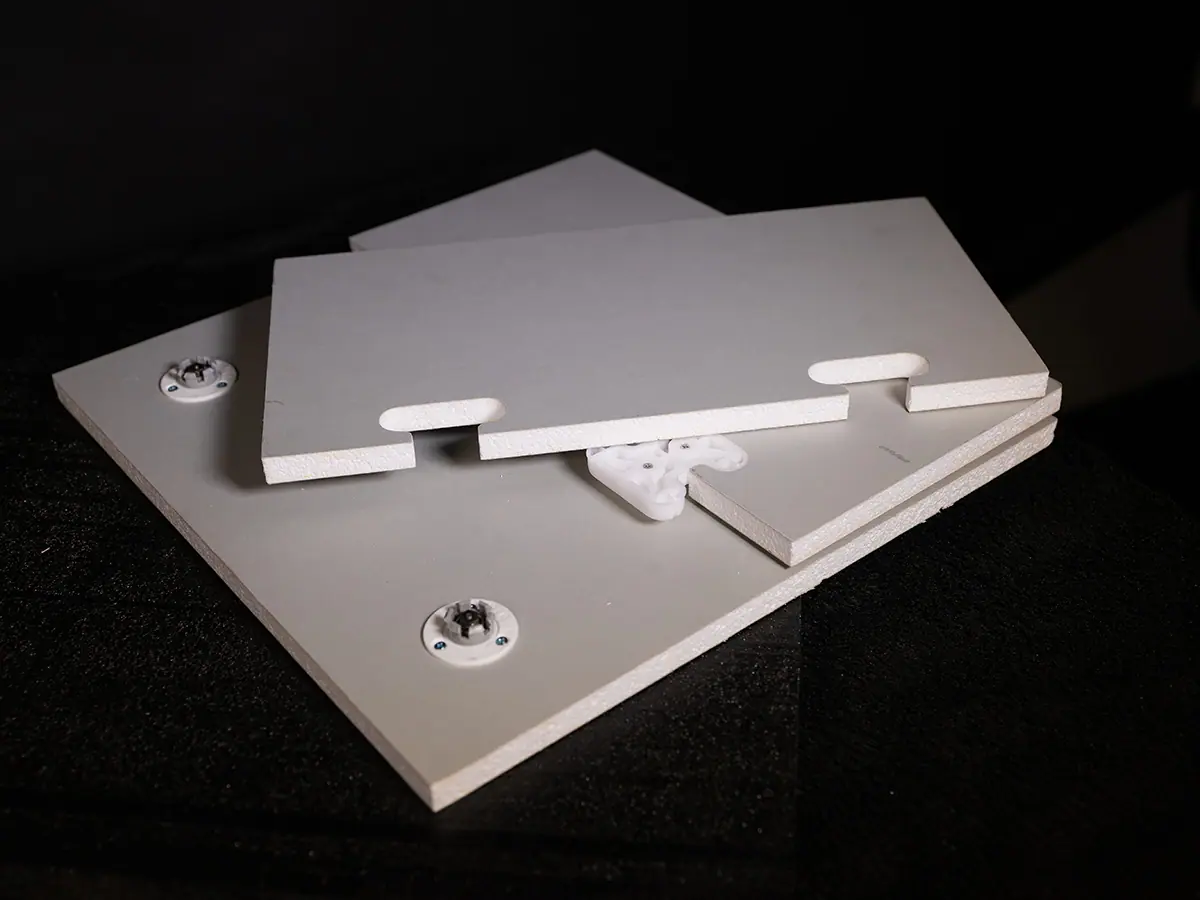

Lightweight sandwich panels

for lightweight sandwiches

As a construction core in sandwich panels, COMPACFOAM makes it possible to reduce the interior weight by up to 50%.

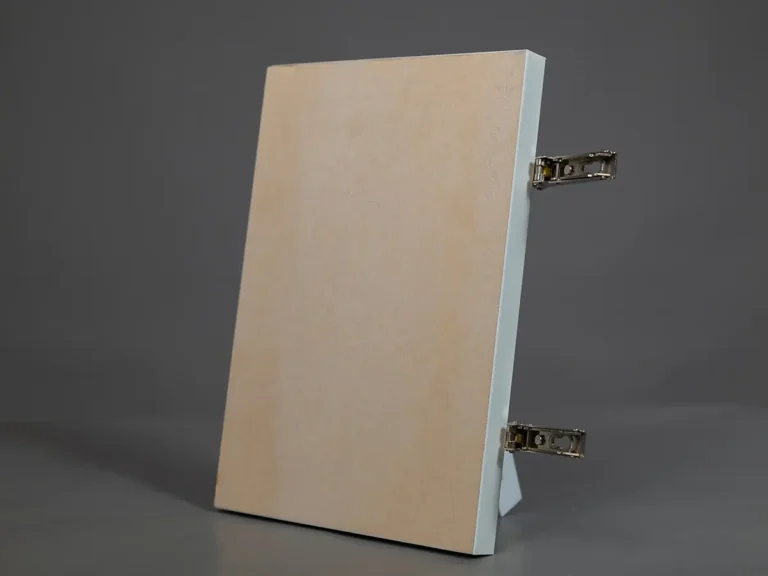

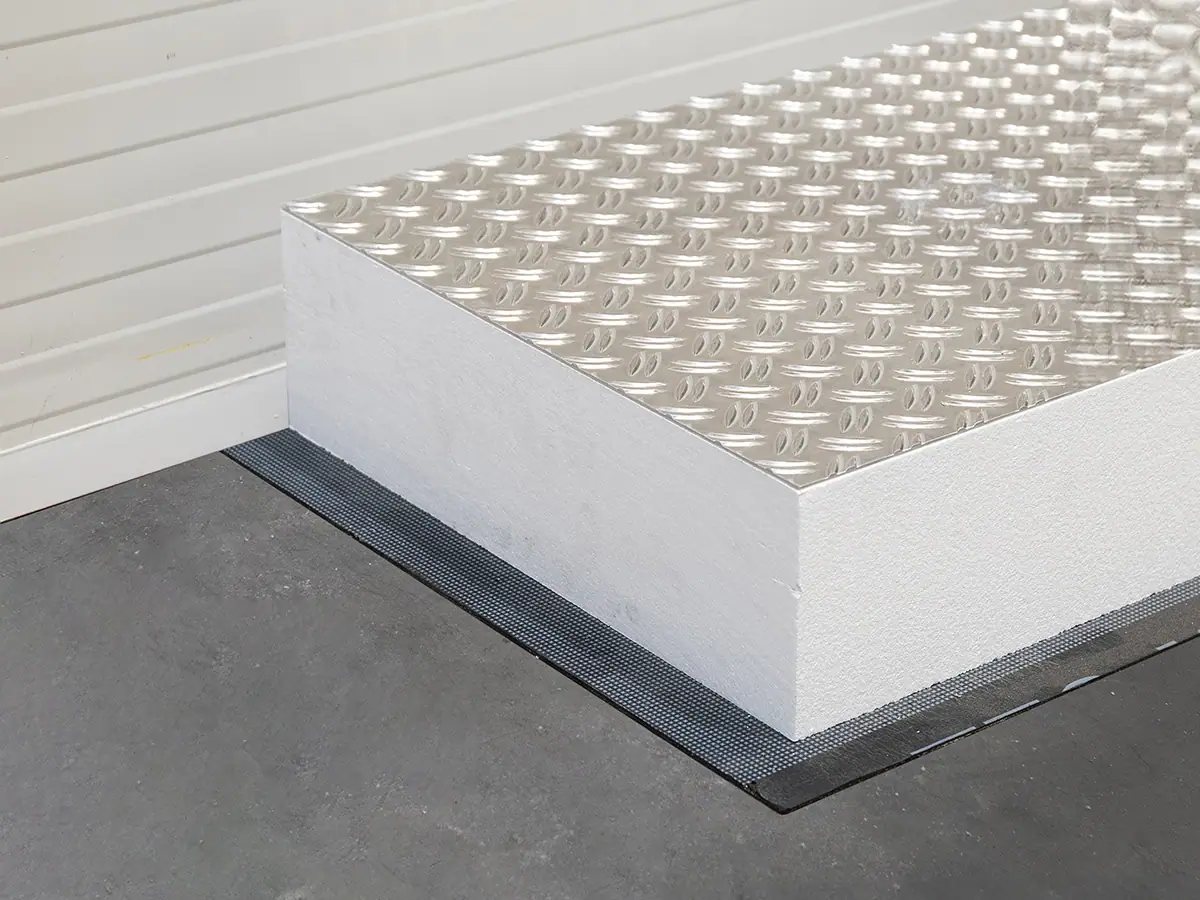

Lightweight assembly components

for mounting

COMPACFOAM is ideal as a component that is inserted into walls to provide a stable and durable fixing – without the weight of traditional materials.

Comparisonwith traditional materials

COMPACFOAM combines strength with excellent thermal insulation and low weight. As a flexible construction element and high-quality insulating material, it is versatile and easy to work with standard woodworking machines (screwing, drilling, sawing, planing, milling).

The material is resistant to moisture and frost, temperature-stable up to 90°C, not brittle at low temperatures and therefore suitable for refrigeration technology. It does not swell or shrink and is resistant to ageing and rotting.

Available as sandwich panel, panel, bar or profiled bar in standard formats and customized cuts. COMPACFOAM is recyclable and sustainable.

A modern construction material for vehicle construction

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTest COMPACFOAM in your project

See the properties of our construction materials for yourself. Order sample panels in 1210x610mm format – ideal for testing screwability, cutting and processing properties in your vehicle construction project.

Fast delivery: Your sample panels will be delivered directly to your workshop or office within a few days. Pay conveniently by credit card, PayPal or EPS.

Choose from different COMPACFOAM variants the right material thickness and surface for your application. This allows you to find the optimum solution for your vehicle project even before placing a bulk order.

Data sheets

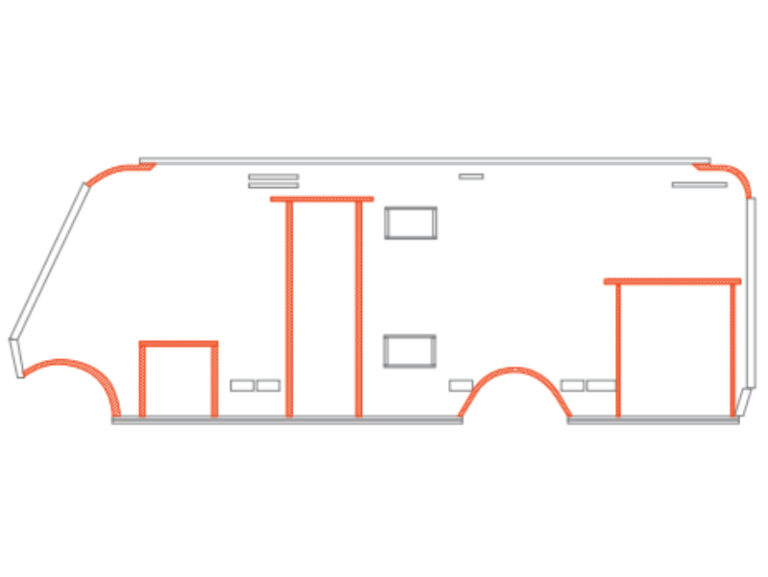

Areas of application in vehicle construction

Every kilogram under 3.5 tons counts

COMPACFOAM enables a weight saving of 200-300kg when insulating your van, without compromising on insulation performance. The material can be screwed directly onto curved sheet metal walls and its closed-cell structure prevents condensation – a critical advantage in compact living spaces. With only 0.5 kg/m² at 20 mm thickness, you maximize your load reserve for equipment and luggage.

Optimum insulation without weight problems

COMPACFOAM offers the perfect balance between thermal insulation and low weight for semi-integrated motorhomes. The material blends seamlessly into the vehicle contour and eliminates thermal bridges thanks to its homogeneous structure. The easy screwability enables professional installation even with complex wall layouts, while the condensation-resistant properties ensure a healthy living climate.

Generous living comfort thanks to intelligent design

Thanks to its low weight, COMPACFOAM enables larger living spaces in fully integrated motorhomes without exceeding the weight limits. The material offers excellent sound and heat insulation for quiet nights and comfortable temperatures. Thanks to the direct screwability without pre-drilling, stable connections are created for furniture fastenings and wall paneling – ideal for the high-quality interior fittings of large motorhomes.

Pull more easily, experience more

COMPACFOAM reduces the unladen weight of your caravan by up to 15%, which means lower fuel consumption and more relaxed driving. The closed-cell structure prevents moisture absorption even during seasonal downtime, while the high pull-out strength ensures secure fastenings for interior fittings. The material retains its shape from -40°C to +70°C – perfect for year-round camping.

ATP-compliant cooling with optimum payload

COMPACFOAM fulfills all ATP requirements with a K-value of 0.046 W/m-K and at the same time reduces the body weight by up to 30%. This means more loading volume for the same vehicle class or a higher payload for the same body. The material is permanently dimensionally stable in the event of temperature fluctuations and offers simple repair options in the event of transport damage thanks to its screwability.

Maximum payload thanks to innovative lightweight construction

For refrigerated trailers, COMPACFOAM enables weight savings of 500-800 kg compared to conventional mineral wool insulation. The material retains its ATP-certified insulating properties even after years of intensive use and eliminates the problem of sagging insulation. The mechanical strength ensures secure fastenings for load securing systems even when fully loaded.

Temperature stability for critical goods

COMPACFOAM offers the temperature stability required for GDP-compliant pharmaceutical transportation with minimal intrinsic mass. The material shows no outgassing and is resistant to disinfectants – essential for transporting medicines. The homogeneous insulation layer eliminates thermal bridges that could lead to temperature fluctuations, while the ease of cleaning ensures hygienic standards.

Robust for extreme conditions

COMPACFOAM withstands temperatures from -40°C to +70°C without loss of properties – ideal for expedition vehicles in all climate zones. The material is insensitive to moisture and UV radiation, while its mechanical strength ensures reliable connections even under off-road conditions. The low thermal conductivity minimizes the energy required for heating and cooling in remote areas without shore power.

Every kilogram under 3.5 tons counts

COMPACFOAM enables a weight saving of 200-300kg when insulating your van, without compromising on insulation performance. The material can be screwed directly onto curved sheet metal walls and its closed-cell structure prevents condensation – a critical advantage in compact living spaces. With only 0.5 kg/m² at 20 mm thickness, you maximize your load reserve for equipment and luggage.

partially integrated

Optimum insulation without weight problems

COMPACFOAM offers the perfect balance between thermal insulation and low weight for semi-integrated motorhomes. The material blends seamlessly into the vehicle contour and eliminates thermal bridges thanks to its homogeneous structure. The easy screwability enables professional installation even with complex wall layouts, while the condensation-resistant properties ensure a healthy living climate.

Fully integrated

Generous living comfort thanks to intelligent design

Thanks to its low weight, COMPACFOAM enables larger living spaces in fully integrated motorhomes without exceeding the weight limits. The material offers excellent sound and heat insulation for quiet nights and comfortable temperatures. Thanks to the direct screwability without pre-drilling, stable connections are created for furniture fastenings and wall paneling – ideal for the high-quality interior fittings of large motorhomes.

Pull more easily, experience more

COMPACFOAM reduces the unladen weight of your caravan by up to 15%, which means lower fuel consumption and more relaxed driving. The closed-cell structure prevents moisture absorption even during seasonal downtime, while the high pull-out strength ensures secure fastenings for interior fittings. The material retains its shape from -40°C to +70°C – perfect for year-round camping.

ATP-compliant cooling with optimum payload

COMPACFOAM fulfills all ATP requirements with a K-value of 0.046 W/m-K and at the same time reduces the body weight by up to 30%. This means more loading volume for the same vehicle class or a higher payload for the same body. The material is permanently dimensionally stable in the event of temperature fluctuations and offers simple repair options in the event of transport damage thanks to its screwability.

(semitrailer)

Maximum payload thanks to innovative lightweight construction

For refrigerated trailers, COMPACFOAM enables weight savings of 500-800 kg compared to conventional mineral wool insulation. The material retains its ATP-certified insulating properties even after years of intensive use and eliminates the problem of sagging insulation. The mechanical strength ensures secure fastenings for load securing systems even when fully loaded.

Temperature stability for critical goods

COMPACFOAM offers the temperature stability required for GDP-compliant pharmaceutical transportation with minimal intrinsic mass. The material shows no outgassing and is resistant to disinfectants – essential for transporting medicines. The homogeneous insulation layer eliminates thermal bridges that could lead to temperature fluctuations, while the ease of cleaning ensures hygienic standards.

Robust for extreme conditions

COMPACFOAM withstands temperatures from -40°C to +70°C without loss of properties – ideal for expedition vehicles in all climate zones. The material is insensitive to moisture and UV radiation, while its mechanical strength ensures reliable connections even under off-road conditions. The low thermal conductivity minimizes the energy required for heating and cooling in remote areas without shore power.

Light

Edges can be glued

Climate stable

Recyclable

Screwable

Waterproof

Customer testimonials

“The material is incredibly light, which helps us to maximize the payload without compromising on stability.”

Markus L.

Production manager

“Always dimensionally stable even at extreme temperatures – a real improvement.”

Simone B.

Managing Director

“The material can be processed like wood, so we didn’t need any expensive machines or changes in production.”

Stefan H.

Design engineer

Why COMPACFOAM?

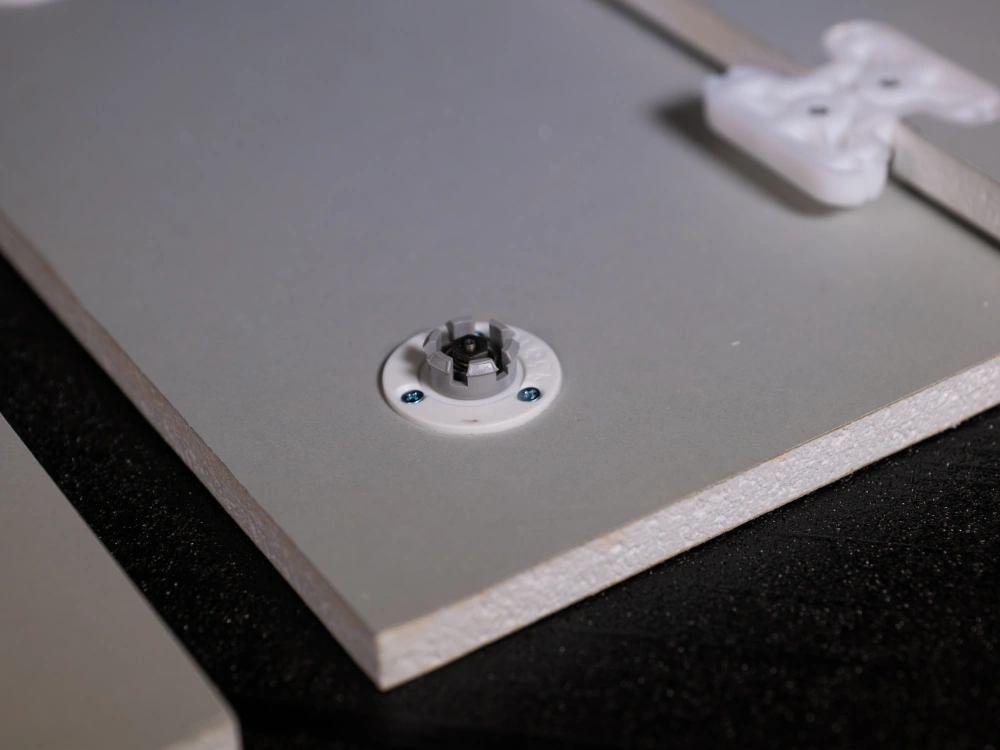

Simple and secure screw connection

COMPACFOAM can be easily screwed together with standard wood screws, ensuring a stable and durable connection. With pull-out strengths comparable to wood-based materials, but at only half the weight, the material is particularly suitable for inserts and fastenings in caravans and refrigerated trailers.

Request a sample

Significant weight saving

One of the most outstanding features of COMPACFOAM is its low weight. Compared to traditional materials such as plywood or MDF, the overall weight of the vehicle is significantly reduced. This leads to higher payloads and enables better fuel efficiency and performance.

Request a sample

Unsurpassed dimensional stability

COMPACFOAM is extremely dimensionally stable. There are no changes in thickness or deflection over the entire service life. The material does not react to changes in humidity or extreme temperatures and always retains its original shape. This ensures consistent performance and prevents deformation over time.

Request a sample

Insensitive to the effects of moisture

Unlike many other materials, which change their structure or even become irreparably damaged when exposed to moisture, COMPACFOAM remains stable even when constantly exposed to moisture. This moisture resistance makes it the ideal choice for use in refrigerated trailers and in vehicles exposed to extreme climatic conditions.

Request a sample

Perfect as a construction core

As a construction core in sandwich panels, COMPACFOAM makes it possible to reduce the interior weight by up to 50%. It remains just as stable and can be screwed together just as easily as wood. This property not only helps to reduce the weight of the vehicle, but also improves the durability and moisture resistance of the panels.

Request a sample

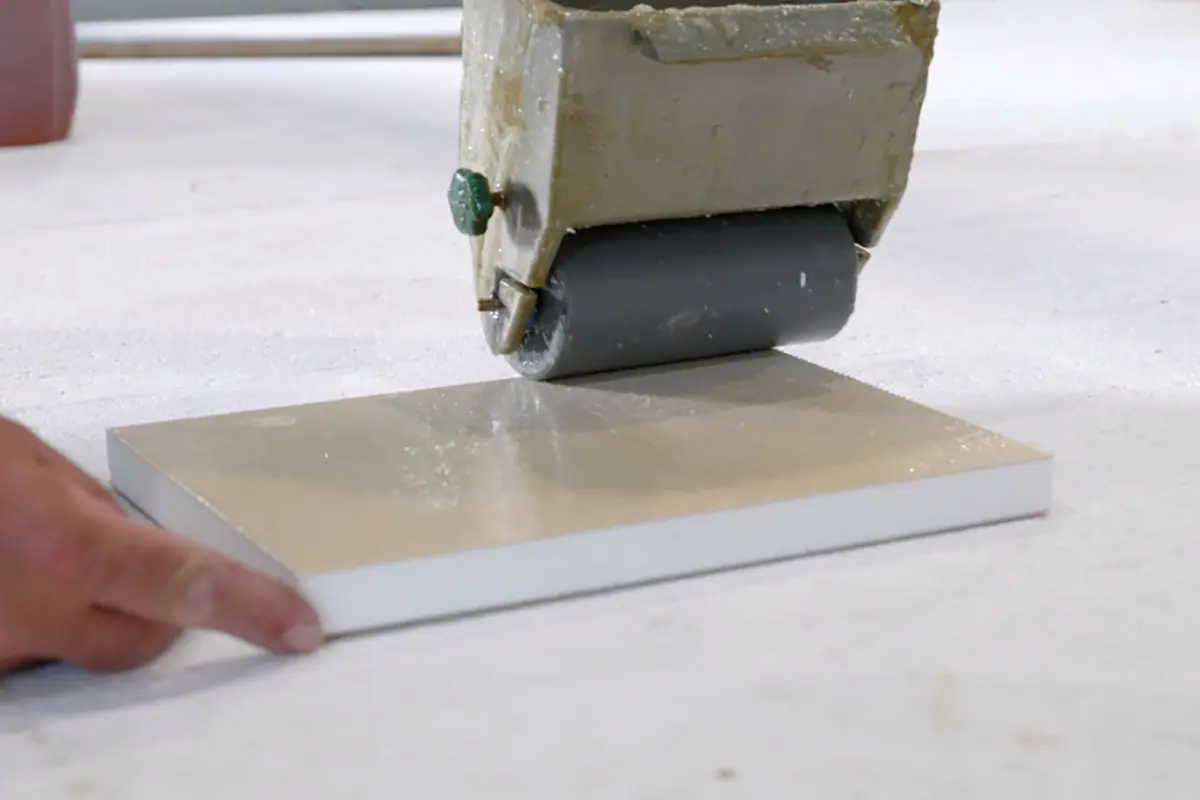

Simple integration into existing production processes

COMPACFOAM can be integrated into existing production processes without additional conversion. It can be processed with the same machines as wood, including cutting, milling and gluing. Screwing directly into the material also works in the same way as with wood, which enables quick adaptation to your production processes.

Sample requests

Maximum durability and resistance

Thanks to its unique composition, COMPACFOAM remains stable, resistant and resilient for years. The high resistance to external influences such as moisture and temperature ensures that your vehicles last longer and are less susceptible to damage.

Request a sample

Savings on operating costs

The lower weight of COMPACFOAM allows you to increase the payload of your vehicle while optimizing fuel consumption. This leads to a reduction in operating costs and better profitability over the life of the vehicle.

Request a sample

COMPACFOAM can be easily screwed together with standard wood screws, ensuring a stable and durable connection. With pull-out strengths comparable to wood-based materials, but at only half the weight, the material is particularly suitable for inserts and fastenings in caravans and refrigerated trailers.

COMPACFOAM is extremely dimensionally stable. There are no changes in thickness or deflection over the entire service life. The material does not react to changes in humidity or extreme temperatures and always retains its original shape. This ensures consistent performance and prevents deformation over time.

Unlike many other materials, which change their structure or even become irreparably damaged when exposed to moisture, COMPACFOAM remains stable even when constantly exposed to moisture. This moisture resistance makes it the ideal choice for use in refrigerated trailers and in vehicles exposed to extreme climatic conditions.

As a construction core in sandwich panels, COMPACFOAM makes it possible to reduce the interior weight by up to 50%. It remains just as stable and can be screwed together just as easily as wood. This property not only helps to reduce the weight of the vehicle, but also improves the durability and moisture resistance of the panels.

COMPACFOAM can be integrated into existing production processes without additional conversion. It can be processed with the same machines as wood, including cutting, milling and gluing. Screwing directly into the material also works in the same way as with wood, which enables quick adaptation to your production processes.

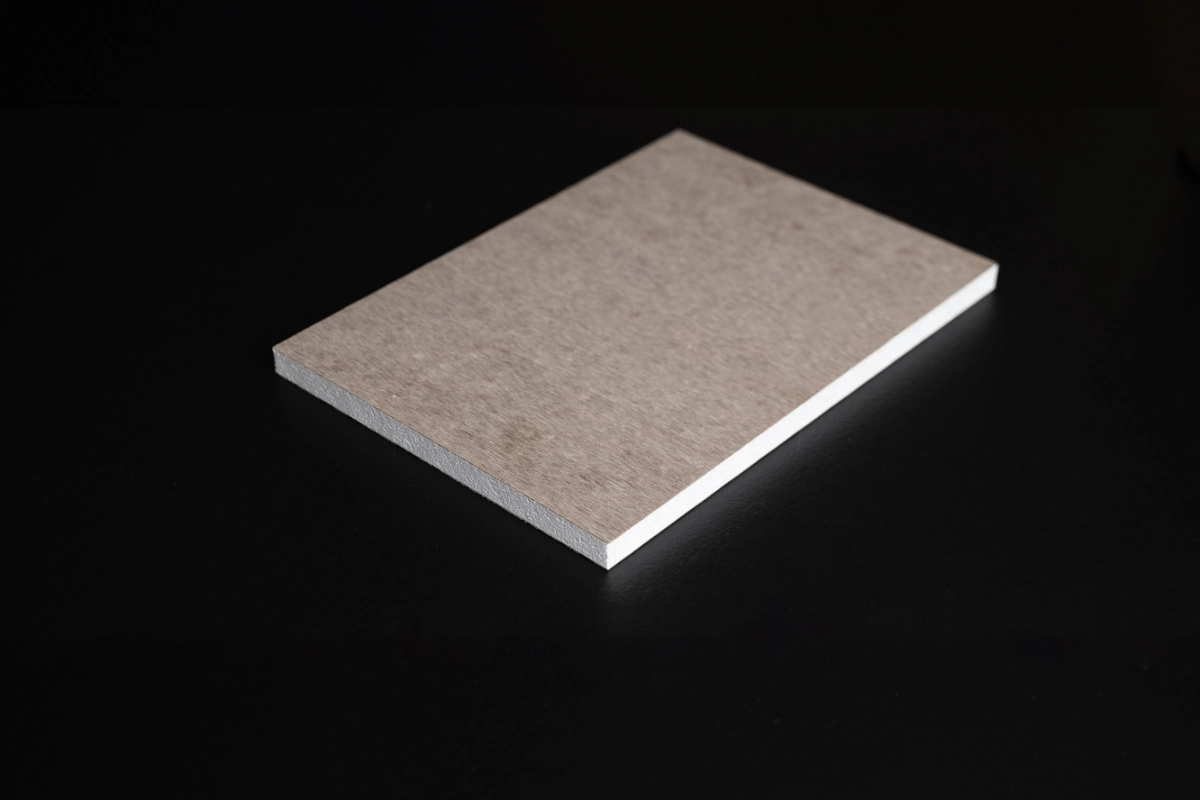

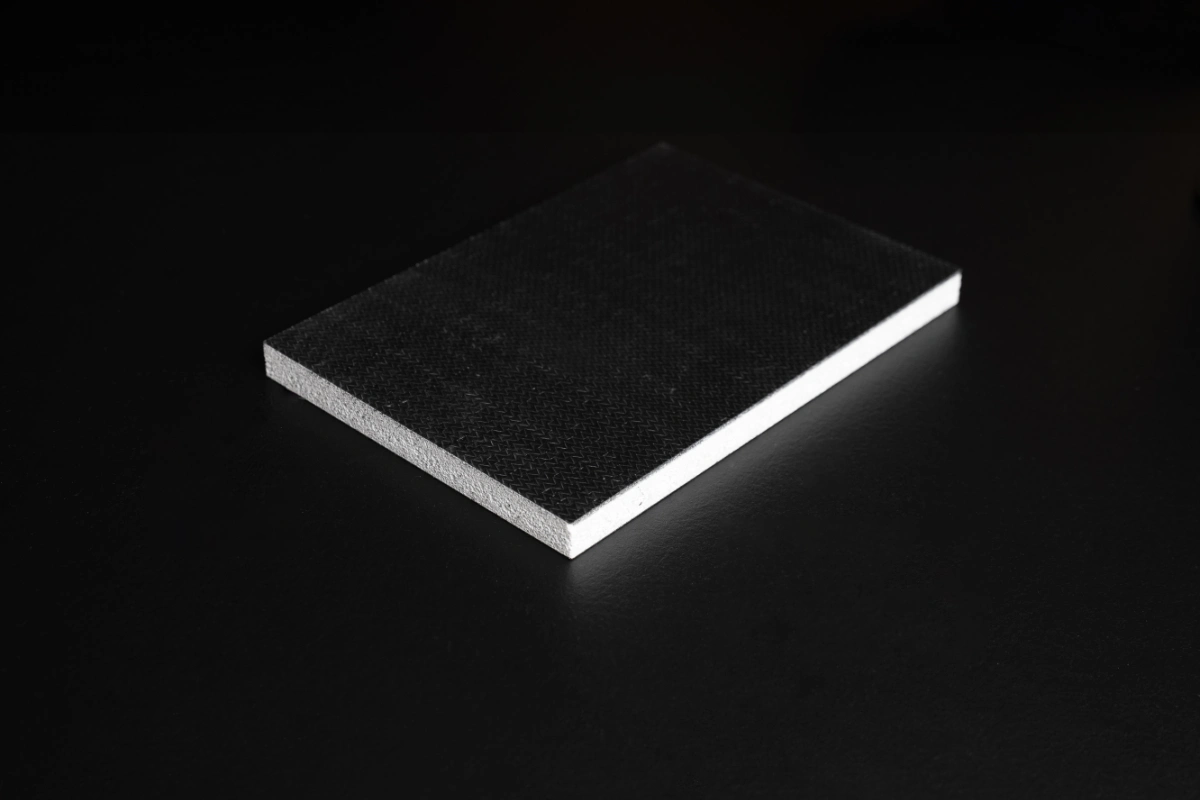

Delivery forms

Perfect for maximum flexibility.

Perfect for interior fittings.

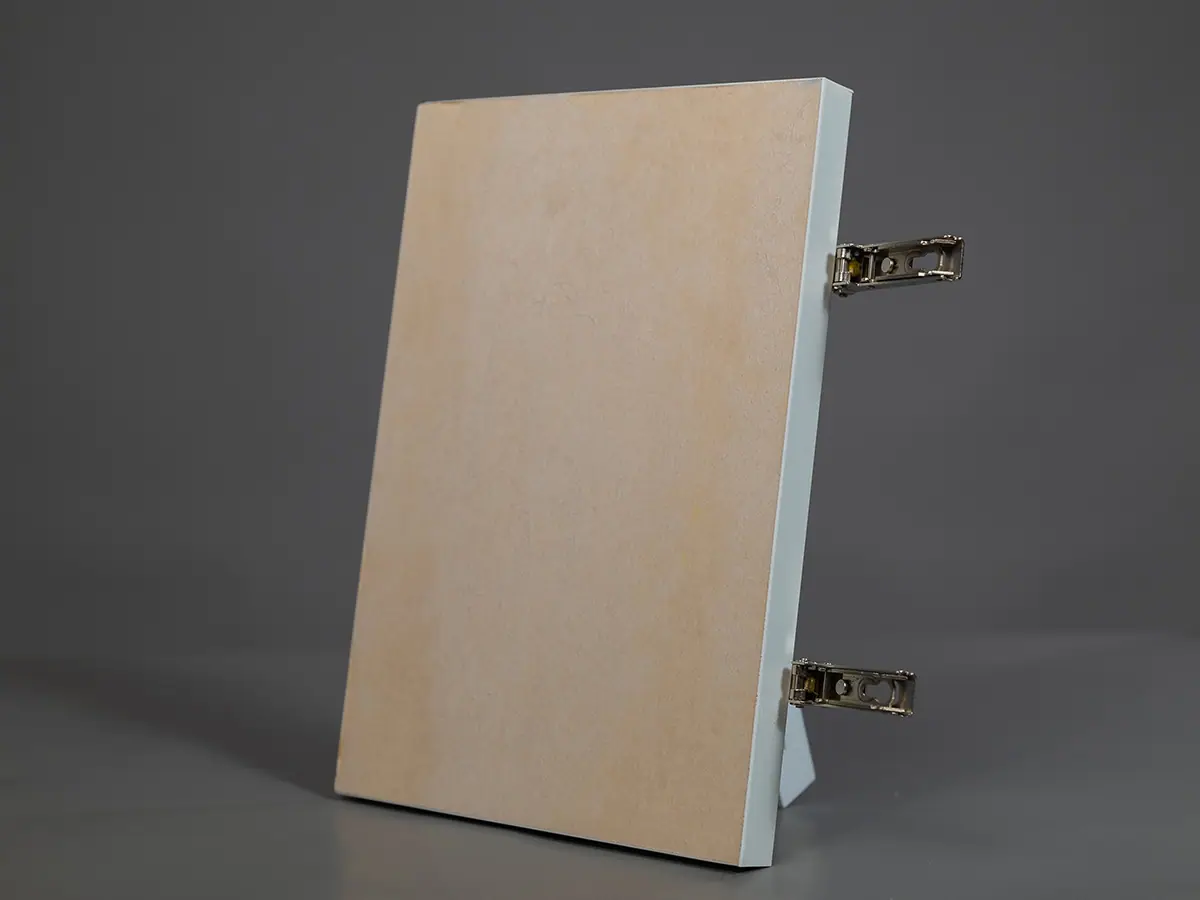

Panels with coating

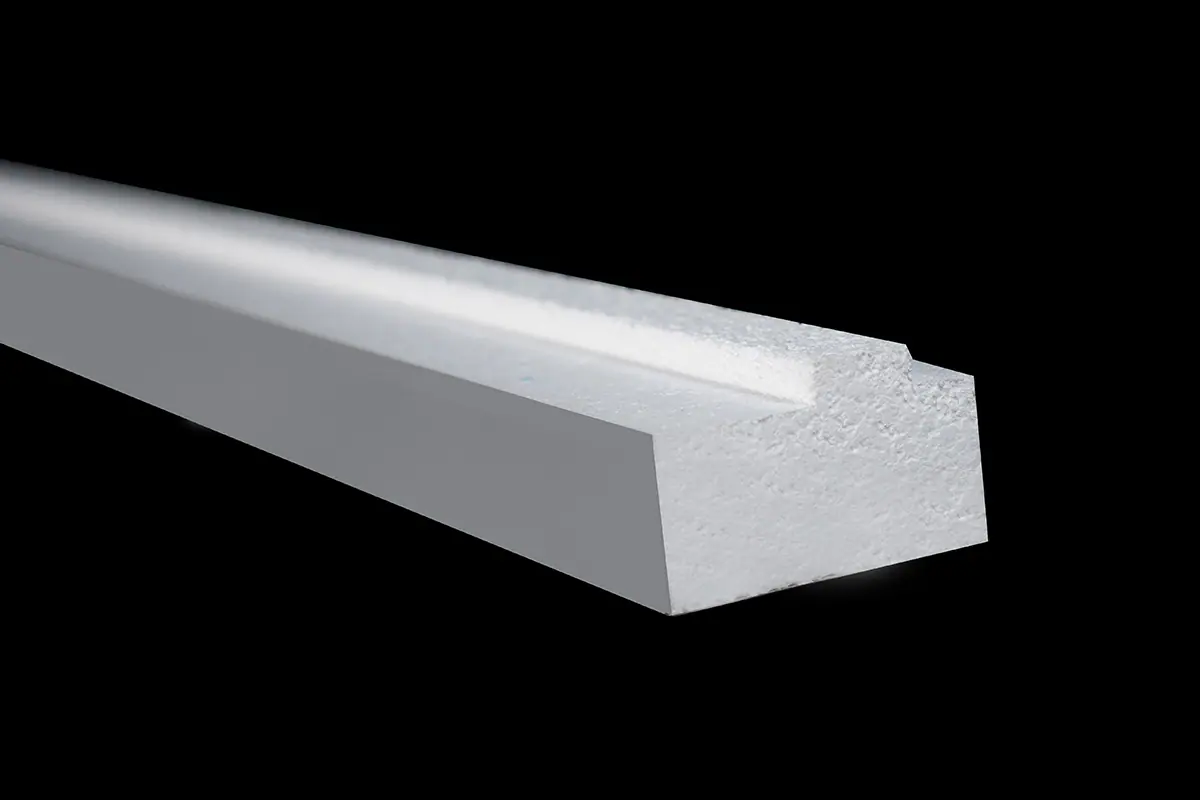

Perfectly adapted to the installation situation, e.g. for frame and edge reinforcement.

(Profiled) rectangular bars

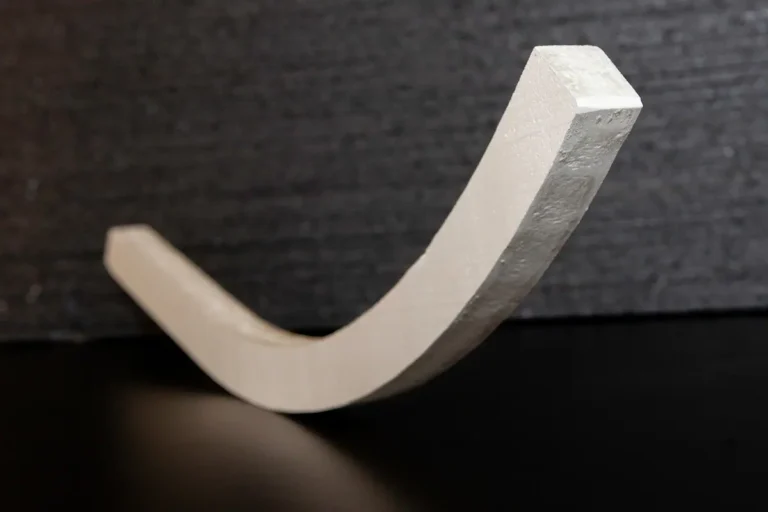

Perfectly adapted to the installation situation, e.g. for wheel arches.

Free molded parts

Videos

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCOMPACFOAM – structural lightweight panels. Dimensional stability

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Informationstructural lightweight sandwich panels. Milling of hardware connection elements

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationLightweight structural panels Lamello fasteners

Tested by

FAQ

COMPACFOAM is significantly lighter than standard wood-based materials, but can be used identically. It can be screwed together and shows no changes when exposed to moisture. This makes it a direct replacement for wood-based materials without the need for fundamental design changes.

COMPACFOAM is up to 70% lighter than wood-based materials, but just as workable and similarly stable. Load-bearing screws can be screwed in directly and furniture edges and millings can be attached without any problems. In contrast to wood-based materials and many other functional and lightweight materials, the material is completely insensitive to moisture and dimensionally stable. Thanks to the special manufacturing process, it does not swell or shrink – the boards do not bend, even under changing temperature and humidity conditions.

COMPACFOAM has thermal conductivity values of 0.037-0.045 W/m²K – this is around three times better than wood-based materials and comparable to polystyrene and lightweight rock wool insulation materials, but with the highest strength at the same time.

COMPACFOAM is completely unmixed and manufactured without the addition of adhesives, blowing agents or additives. This makes it completely formaldehyde-free and free of all hazardous or carcinogenic additives. COMPACFOAM is manufactured with a high proportion of recycled components and is of course itself completely recyclable.

COMPACFOAM is always adapted exactly to your requirements. This largely avoids cutting costs and eliminates the need for time-consuming processing at the customer’s premises.

COMPACFOAM is permanently resistant even under the influence of moisture and high temperatures. This prevents a shortened service life due to unwanted moisture ingress or extreme temperatures.

COMPACFOAM can be processed in much the same way as wood. This means that no additional or different work steps are required. In addition, the uniqueness of the material often replaces complex multi-layer structures with a simple solution.

COMPACFOAM is 100% recyclable and also available in a 100% recycled version. This makes it a sustainable alternative for environmentally conscious vehicle manufacturers.