The lightweight material for construction and insulation

to our productsA modern material made from pure raw material

It combines strength with excellent thermal insulation and a very low weight. The functional material COMPACFOAM is both a flexible construction element and a high-quality insulating material. This combination makes COMPACFOAM particularly versatile and high-quality.

Our panels, rods, profile bars and cubes have a comparatively low weight. This makes them easier to handle. They are also easy to screw, drill, saw, thickness-calibrate and mill using standard woodworking machines.

Thanks to its ductile properties, the functional material compensates for unevenness in the substrate without causing damage. COMPACFOAM is insensitive to moisture and frost. This prevents swelling and shrinkage and makes the material resistant to ageing and rotting as well as rot-proof.

The product range extends from standard panels for flexible further processing to customized cut-to-size products according to customer specifications.

COMPACFOAM is recyclable, unmixed and meets all requirements for sustainable, environmentally friendly construction. Our products are listed with DGNB. Thanks to its properties, COMPACFOAM opens up new solutions in modern construction.

Low dead weight

Highly resilient

100% recyclable

Material return

Highly insulating

Simple processing

Open to diffusion

Biocide-free

Low dead weight

Highly resilient

100% recyclable

Material return

Highly insulating

Simple processing

Open to diffusion

Biocide-free

Areas of application

COMPACFOAM is used in window construction due to its low weight, high stability and excellent thermal insulation. It is ideal for spacer profiles and fixing elements, providing a durable and energy-efficient solution for window constructions.

for window construction

In façade construction, COMPACFOAM is used as an insulating and construction material. It is moisture-resistant, climate-stable and dimensionally stable, which ensures a long service life and excellent insulating properties. Ideal for ventilated façades and other applications where lightness and stability are required.

For facade construction

COMPACFOAM is used in metal construction as a lightweight but highly resilient material. It can be used as a substructure, insulation or reinforcement. Its high screw pull-out strength and compressive stability make it particularly suitable for load-bearing and structural elements.

to metal construction

COMPACFOAM is used in timber construction as a rot-proof alternative to wood. It can be processed in the same way as wood (sawing, milling, drilling), but does not rot or mold, while offering high compressive strength and excellent thermal insulation. Ideal for base areas, thresholds, and window/door reveals, where moisture protection and load-bearing capacity are crucial.

to timber construction

Yacht building requires materials that are light, waterproof and stable. COMPACFOAM meets these requirements and is used for furniture, wall paneling, insulation and structural components on yachts. It resists moisture and salt water and ensures a long service life for the components.

for yacht building

Effective thermal insulation is essential in refrigeration technology. COMPACFOAM offers excellent insulation performance and is used for cold rooms, air conditioning systems and insulating elements in refrigeration systems. It reduces heat loss and increases energy efficiency.

to refrigeration technology

In furniture construction, COMPACFOAM is used due to its lightness, workability and stability. It is suitable for sandwich panels, furniture core materials and cladding elements. The possibility of coating with HPL, veneer or laminate makes it versatile.

for furniture construction

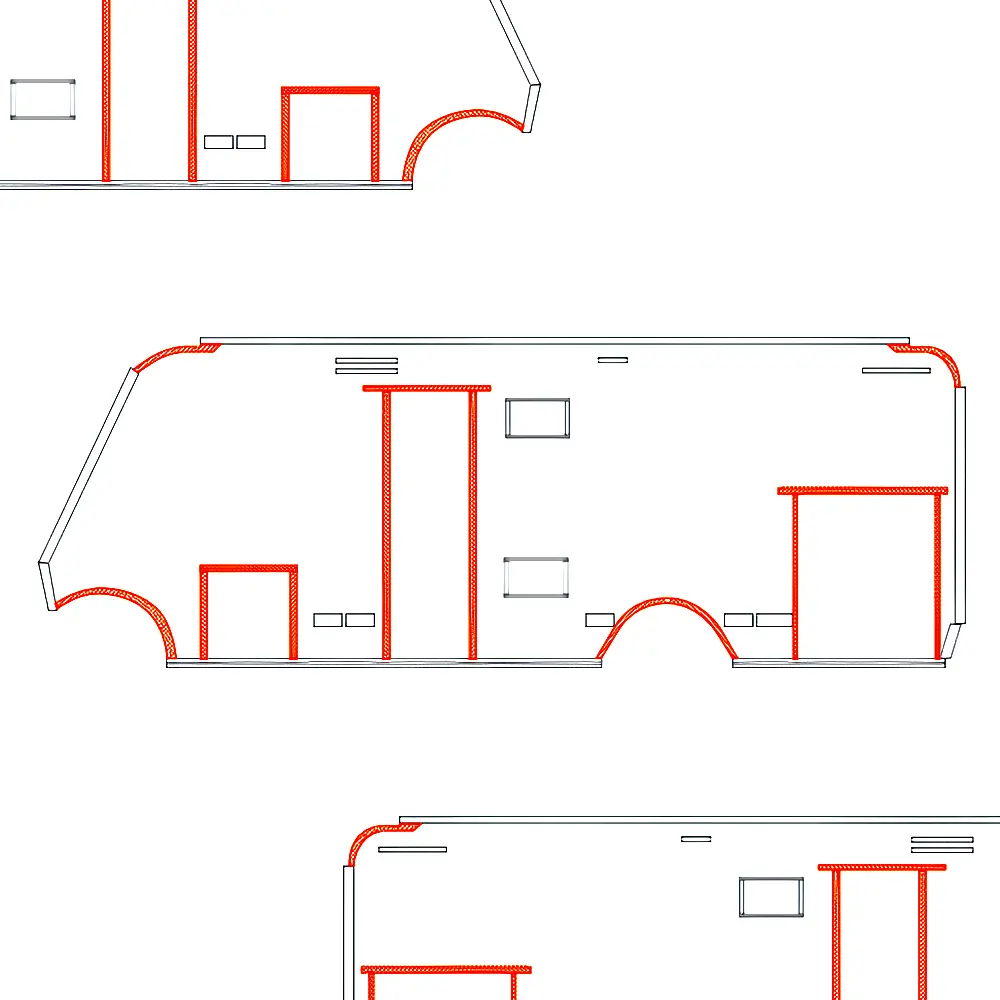

Weight is a decisive factor in vehicle construction. COMPACFOAM offers an ideal combination of low weight and high stability. It is used for wall and floor structures, insulating materials and load-bearing elements in motorhomes and caravans.

for vehicle construction

When installing sun protection systems such as roller shutters, blinds and awnings, COMPACFOAM is used as a load-bearing and insulating material. It ensures a high level of thermal insulation and at the same time provides a stable basis for fixing sun protection elements.

for sun protection

COMPACFOAM is used in window construction due to its low weight, high stability and excellent thermal insulation. It is ideal for spacer profiles and fixing elements, providing a durable and energy-efficient solution for window constructions.

In façade construction, COMPACFOAM is used as an insulating and construction material. It is moisture-resistant, climate-stable and dimensionally stable, which ensures a long service life and excellent insulating properties. Ideal for ventilated façades and other applications where lightness and stability are required.

COMPACFOAM is used in metal construction as a lightweight but highly resilient material. It can be used as a substructure, insulation or reinforcement. Its high screw pull-out strength and compressive stability make it particularly suitable for load-bearing and structural elements.

COMPACFOAM is used in timber construction as a rot-proof alternative to wood. It can be processed in the same way as wood (sawing, milling, drilling), but does not rot or mold, while offering high compressive strength and excellent thermal insulation. Ideal for base areas, thresholds, and window/door reveals, where moisture protection and load-bearing capacity are crucial.

Yacht building requires materials that are light, waterproof and stable. COMPACFOAM meets these requirements and is used for furniture, wall paneling, insulation and structural components on yachts. It resists moisture and salt water and ensures a long service life for the components.

Effective thermal insulation is essential in refrigeration technology. COMPACFOAM offers excellent insulation performance and is used for cold rooms, air conditioning systems and insulating elements in refrigeration systems. It reduces heat loss and increases energy efficiency.

In furniture construction, COMPACFOAM is used due to its lightness, workability and stability. It is suitable for sandwich panels, furniture core materials and cladding elements. The possibility of coating with HPL, veneer or laminate makes it versatile.

Weight is a decisive factor in vehicle construction. COMPACFOAM offers an ideal combination of low weight and high stability. It is used for wall and floor structures, insulating materials and load-bearing elements in motorhomes and caravans.

When installing sun protection systems such as roller shutters, blinds and awnings, COMPACFOAM is used as a load-bearing and insulating material. It ensures a high level of thermal insulation and at the same time provides a stable basis for fixing sun protection elements.

Recycling

Material in the cycle instead of disposal costs

If you cut our COMPACFOAM products to fit your needs exactly, you will automatically have offcuts – and you will incur disposal costs.

You can also feed the offcuts back into the material cycle. We are happy to collect the offcuts and recycle them into a new, high-quality construction material.

This turns COMPACFOAM back into COMPACFOAM, or more precisely CFeco. Your added value: you increase the proportion of recycled material in your design and improve your company’s eco-balance. Because environmental protection means keeping things in circulation instead of disposing of them at great expense.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationEditing

Read moreSaws

COMPACFOAM can be easily cut to size with standard (wood) saws.

Planing

COMPACFOAM can be planed precisely, with tolerances of ±0.3 mm.

Profiling

COMPACFOAM can be easily profiled with standard wood milling machines or four-sided machines.

Coating

COMPACFOAM can be coated in a variety of ways, e.g. with PVC, HPL, kraft paper, MDF, laminate, veneers and synthetic resins

CNC machining

COMPACFOAM can be machined on CNC systems with the highest precision, e.g. for 3D milling.

Loops

COMPACFOAM can be ground precisely with tolerances of ±0.2 mm.

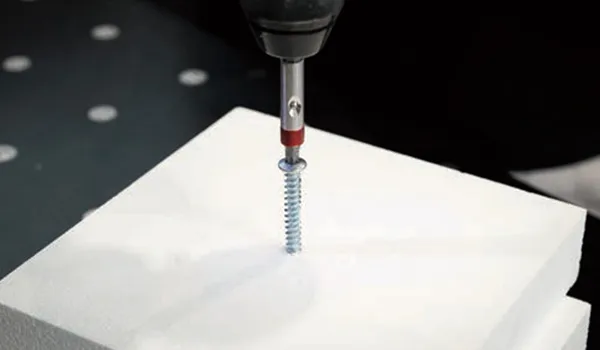

Screws

COMPACFOAM can be screwed together perfectly without pre-drilling.

Edges

Edges can be easily applied using conventional methods

Properties

Resistant to rotting

COMPACFOAM is a material that neither molds nor rots. Thanks to this property, it remains permanently stable and resistant even under extreme conditions. Perfect for all applications where durability and reliability are required!

Light

COMPACFOAM combines exceptional strength with minimal weight – ideal for anyone looking for lightweight yet robust solutions!

Dimensionally stable

COMPACFOAM remains absolutely dimensionally stable under all conditions, regardless of temperature changes, frost or moisture. This property ensures unlimited long-term stability and extends the service life of the surrounding products.

Climate stable

COMPACFOAM is insensitive to moisture, temperature and frost, yet is breathable and open to diffusion. This is particularly important when in contact with wood. Any moisture that has penetrated dries out without causing damage. Excellent durability in damp and salty environments. No change in material properties over time.

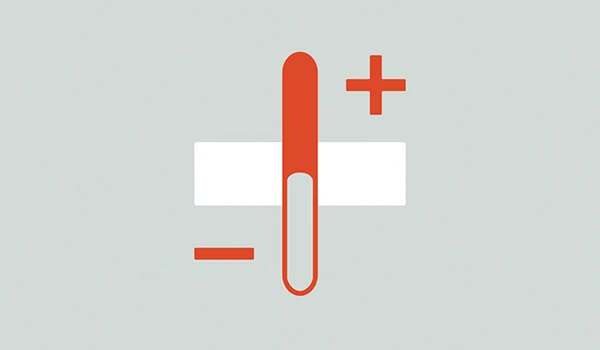

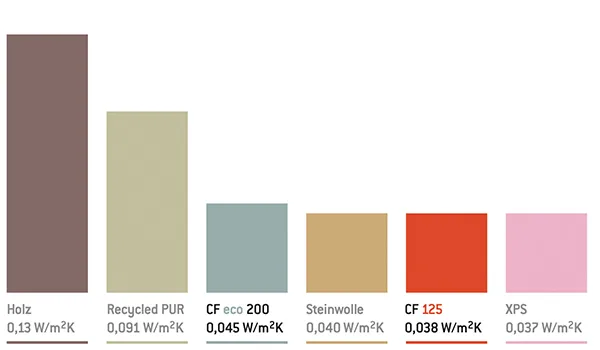

Excellent thermal insulation

COMPACFOAM impresses with thermal insulation that is twice as efficient as conventional PU recycled materials. Our innovative material combines excellent insulation performance with high stability. This not only reduces your energy costs, but also makes an important contribution to environmental protection.

W/m²K is the unit of the heat transfer coefficient, also known as the U-value. It indicates how much heat flows through a component at a certain temperature difference. The lower the value, the better the insulating properties.

Screwable

COMPACFOAM is easy to screw together without pre-drilling. We recommend wood screws or window frame screws for secure and stable fastening.

Highly resilient

COMPACFOAM is characterized by excellent compressive strength and remains permanently dimensionally stable. It can withstand extreme loads and guarantees long-term reliability and stability.

Biocide-free

COMPACFOAM is unmixed and does not release any harmful chemical substances. No harmful dusts or vapors are produced during processing.

COMPACFOAM combines exceptional strength with minimal weight – ideal for anyone looking for lightweight yet robust solutions!

COMPACFOAM is insensitive to moisture, temperature and frost, yet is breathable and open to diffusion. This is particularly important when in contact with wood. Any moisture that has penetrated dries out without causing damage. Excellent durability in damp and salty environments. No change in material properties over time.

W/m²K is the unit of the heat transfer coefficient, also known as the U-value. It indicates how much heat flows through a component at a certain temperature difference. The lower the value, the better the insulating properties.

COMPACFOAM impresses with thermal insulation that is twice as efficient as conventional PU recycled materials. Our innovative material combines excellent insulation performance with high stability. This not only reduces your energy costs, but also makes an important contribution to environmental protection.

Delivery forms

To the productsPlates

Sanded and planed panels for sandwiches

(Profiled) bars

Machined molded parts

Coated rods and sheets

Composite parts